Double girder overhead cranes are widely recognized for their robustness, high lifting capacities, and ability to handle heavy-duty industrial applications. One of the most critical components in their design is the trolley system, which carries the hoist and traverses along the girders to position loads precisely. The configuration of the trolley directly influences the crane’s load handling efficiency, safety, and suitability for different working environments. Understanding trolley configurations in double girder overhead cranes helps engineers, operators, and buyers select the right setup to optimize performance.

This article explores the importance of trolley configuration, types, design considerations, applications, and advantages for different industrial needs.

Importance of Trolley Configuration

The trolley serves as the mobile platform that supports the hoisting mechanism and enables lateral movement along the crane bridge. In double girder overhead cranes, the trolley configuration is particularly important because:

-

Load Distribution – The way the trolley is designed and mounted affects how weight is transferred to the girders and end trucks, impacting structural integrity and wear.

-

Operational Efficiency – Different trolley setups can provide faster load handling, smoother travel, and better positioning accuracy.

-

Space Utilization – Trolley design influences hook approaches and headroom, which are critical in maximizing workspace usage.

-

Customization Potential – Specific industries may require dual trolleys, rotating trolleys, or specialized hoist configurations to handle unique lifting challenges.

Types of Trolley Configurations

1. Normal (Top-Running) Trolley

The most common configuration is the top-running trolley, which travels along the top flange of the double girders.

-

Advantages:

-

High stability due to direct load transfer onto the girders.

-

Capable of handling very high capacities (from 20 ton to 500 ton overhead cranes or more).

-

Offers long service life with proper maintenance.

-

-

Applications: Heavy manufacturing, shipbuilding, and steel mills.

2. Underhung Trolley

In certain cases, a trolley may be underslung between the two girders, though this is less common for heavy loads.

-

Advantages:

-

Allows better hook approach between the girders.

-

Suitable for facilities where maximizing lateral movement is critical.

-

-

Limitations:

-

Reduced load capacity compared to top-running configurations.

-

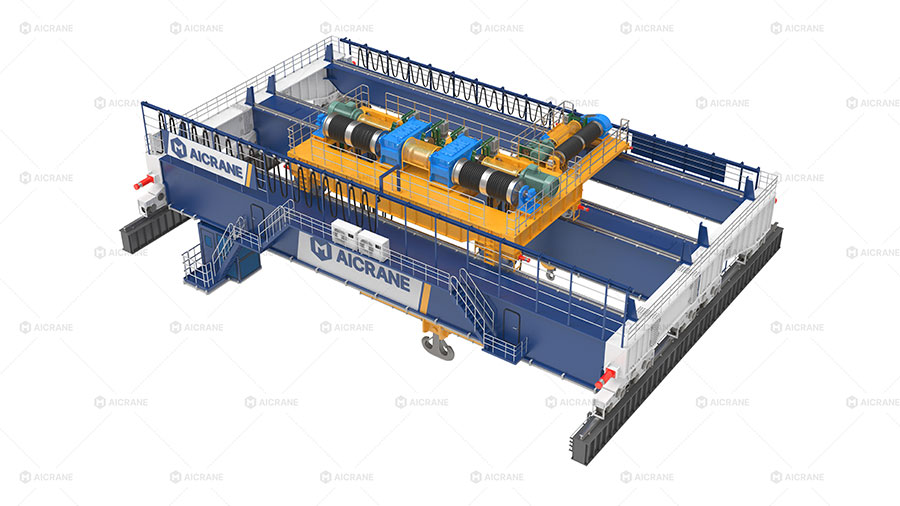

3. Dual Trolley Configuration

Some double girder cranes use two trolleys on the same bridge. They can operate independently or in tandem.

-

Advantages:

-

Flexible handling of long or bulky loads.

-

Tandem lifting improves safety for oversized objects like precast beams, turbines, or steel structures.

-

Independent operation increases efficiency for handling multiple smaller loads.

-

-

Applications: Precast concrete plants, shipyards, heavy equipment assembly.

4. Rotating Trolley

Rotating trolleys are designed with a slewing mechanism that allows the hoist and hook to rotate.

-

Advantages:

-

Enables precise positioning without moving the entire crane.

-

Reduces time spent on aligning loads in confined spaces.

-

-

Applications: Machinery installation, aerospace, and industries requiring delicate load orientation.

5. Auxiliary Trolley (with Main Trolley)

Many double girder eot cranes integrate a main trolley for heavy loads and an auxiliary trolley for lighter lifting tasks.

-

Advantages:

-

Versatility in handling different load categories.

-

Auxiliary hoist can assist during the main lifting process (e.g., flipping components or providing additional support).

-

Increases efficiency when lighter loads need frequent handling without engaging the heavy-duty hoist.

-

-

Applications: Power plants, assembly workshops, metallurgy industries.

Design Considerations for Trolley Configuration

When selecting or designing trolley configurations for double girder overhead cranes, several factors must be considered:

-

Load Capacity

-

Heavy-duty cranes with capacities exceeding 50 tons typically use robust top-running trolleys with reinforced frames.

-

For lighter applications, dual or auxiliary trolleys may improve versatility without oversizing the crane.

-

-

Span Length

-

Longer spans benefit from dual trolley setups, as load balancing is crucial to avoid structural stress.

-

-

Headroom Requirements

-

Facilities with limited vertical clearance may prefer low-headroom trolley designs that maximize lifting height.

-

-

Speed and Control

-

Modern trolleys are equipped with variable frequency drives (VFDs) to ensure smooth acceleration, precise positioning, and reduced load swing.

-

-

Maintenance Accessibility

-

Trolleys should be designed for easy inspection of wheels, gears, motors, and brakes to reduce downtime.

-

-

Safety Standards

-

Compliance with international standards (such as FEM, CMAA, or ISO) ensures that the trolley configuration is structurally sound and safe for long-term use.

-

Applications of Different Trolley Configurations

-

Heavy Manufacturing: Single heavy-duty trolley configurations are common for handling steel coils, castings, and machinery components.

-

Shipbuilding: Dual trolleys or main-and-auxiliary setups allow the handling of massive ship sections and smaller sub-assemblies.

-

Power Stations: Main trolleys lift turbines and generators, while auxiliary trolleys handle maintenance and smaller components.

-

Precast Industry: Dual trolley cranes transport long concrete beams safely and efficiently.

-

Aerospace and Automotive: Rotating trolleys enable precision in component orientation during assembly.

Advantages of Proper Trolley Configuration

-

Enhanced Flexibility – The right configuration allows overhead bridge crane for sale to handle a wider variety of loads.

-

Improved Safety – Tandem trolleys and auxiliary hoists reduce the risks associated with oversized or unbalanced loads.

-

Operational Efficiency – Smooth travel mechanisms and specialized designs minimize downtime and speed up material handling.

-

Extended Equipment Life – Balanced load distribution reduces stress on girders, wheels, and rails, enhancing durability.

-

Customization Potential – Businesses can tailor crane systems to specific needs without overspending on unnecessary capacity.

Trends and Innovations in Trolley Systems

Modern double girder overhead crane trolleys are incorporating advanced technologies:

-

Automation and Remote Control: Operators can control trolley movement with high precision, reducing labor risks.

-

Anti-Sway Control: Intelligent software minimizes load swing during trolley travel.

-

Energy Efficiency: Regenerative drives and optimized motor controls lower energy consumption.

-

Condition Monitoring: Sensors on trolley wheels, motors, and brakes provide real-time data for predictive maintenance.

These advancements make trolley configurations not just a structural necessity, but also a key factor in modernizing material handling systems.

Conclusion

The trolley configuration in double girder overhead cranes is a central design feature that determines how effectively and safely the crane will perform in real-world operations. From simple top-running trolleys to advanced dual and rotating systems, each configuration offers unique advantages suited to specific industries. When choosing a trolley design, factors like load capacity, span, headroom, and operational flexibility must be carefully weighed.

With modern innovations such as VFDs, automation, and anti-sway technologies, trolley systems are evolving into highly efficient, customizable, and intelligent components of overhead crane solutions. By understanding and selecting the right configuration, industries can maximize crane efficiency, improve workplace safety, and achieve long-term reliability in their material handling processes.